About us

We are a manufacturer and service provider of innovative food processing machinery for the meat, poultry and seafood industries. Since 1977, the company has consistently been at the forefront of designing solutions that meet the needs of food processors who demand quality and safety, while maximizing productivity and yields. With a strong commitment to customer satisfaction, Henneken partners with clients to identify the right solution, designs and delivers equipment on-time, and provides reliable service and aftermarket parts support.

In 2024, Henneken established a new partnership with global engineered equipment leader Duravant. Click hereto read the Press Release announcing our next exciting chapter of growth.

Tumbler construction

since 1977

1977 was the year in which Ferdinand Henneken founded the Ferdinand Henneken GmbH produces machines for the meat industry for more than 40 years in Bad Wünnenberg, Germany. The product portfolio encompasses vacuum tumblers, tenderizers, injectors, brine mixers, flatteners and several loading devices.

1983 - In this year Ferdinand Henneken decided to change the location of the production and built the new facility at a location which allows further expansions in the future.

This vision paid off, because the enlargements followed in the years 1993, 1996, 2000, 2012 and 2016 so that nowadays the production area is 6.500 m². In addition to that a modern office building with seminar rooms and a technical center with 1350m² were raised in order to give customers and traders the possibility to test the machines on site.

We pledge to

HIGH QUALITY AND DURATION OF OUR PRODUCTS

PROMPT DELIVERY

THOROUGH AND EXTENSIVE SERVICE

INDIVIDUAL CUSTOMER RELATIONS

BEST COST/PERFORMANCE RATIO IN THE MARKET

Visit us!

Quality &

expertise

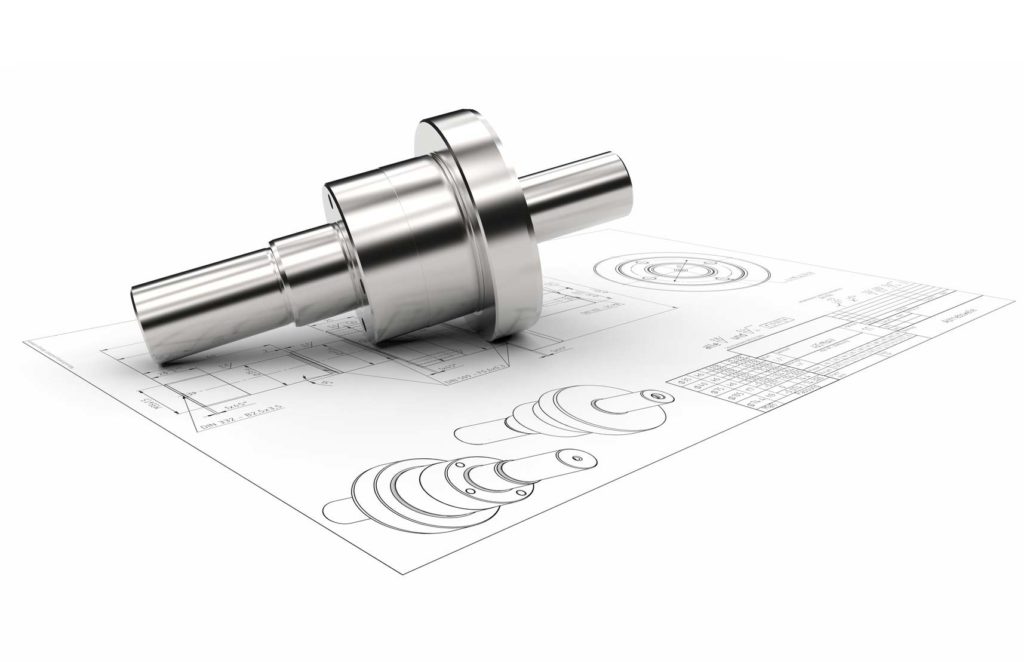

When we develop our machines we attach importance to the cooperation between technicians and technologistsso that the operating and maintainability are in the focus just as well the technological requirements to the end product of the costumer.

In addition to that a high inhouse production depth is important for us, because that guarantees continuous high quality for our customers and flexibility. In order to maintain our high quality standards, we rely on qualified employees that are trained in our facilities and examined by the chamber of commerce. All of our employees are specialists in their respective line of work and distinguish themselves through long experience and a high orientation towards quality. We resign completely from temporary work.

In order to guaranty high quality at built-in purchased parts we use parts from reknown, internationally operating companies like Siemens, Busch and SEW.