Injector HPI

THE PROFITMAKER

For bone-in

and boneless products

The injector HPI is availabe with the working width 300 mm, 350 mm, 450 mm and 650 mm.

The injectors are characterized by its robust industrial design and its ease of maintenance. It was attached importance to unproblematic accessibility to all parts. Only top quality components are built-in.

The injection is suitable for all kinds of meat with and without bones. By a special stripper with height setting it is guaranteed that no product is pressed or injected brine is pressed out. Thus the product is able to increase.

HPI 300

The Henneken injector HPI 300 is the entry starter model of the HPI series. The HPI 300 is an all-rounder which is suitable for bone-in and boneless products. Because of the foldable hood and the fast removal of the stainless-steel racks the machines enables a very good accessibility for a fast and pinpoint cleaning.

With all injector models the brine pressure enables a steppless adjustment from 0,5 to 4 bar. The self-priming stainless-steel pump and our forced injection which is controlled by the stripper plate lead to a very high injection precision.

HPI 350

HPI 450 and 650

HPI 450 S, 650 S AND

1000 S

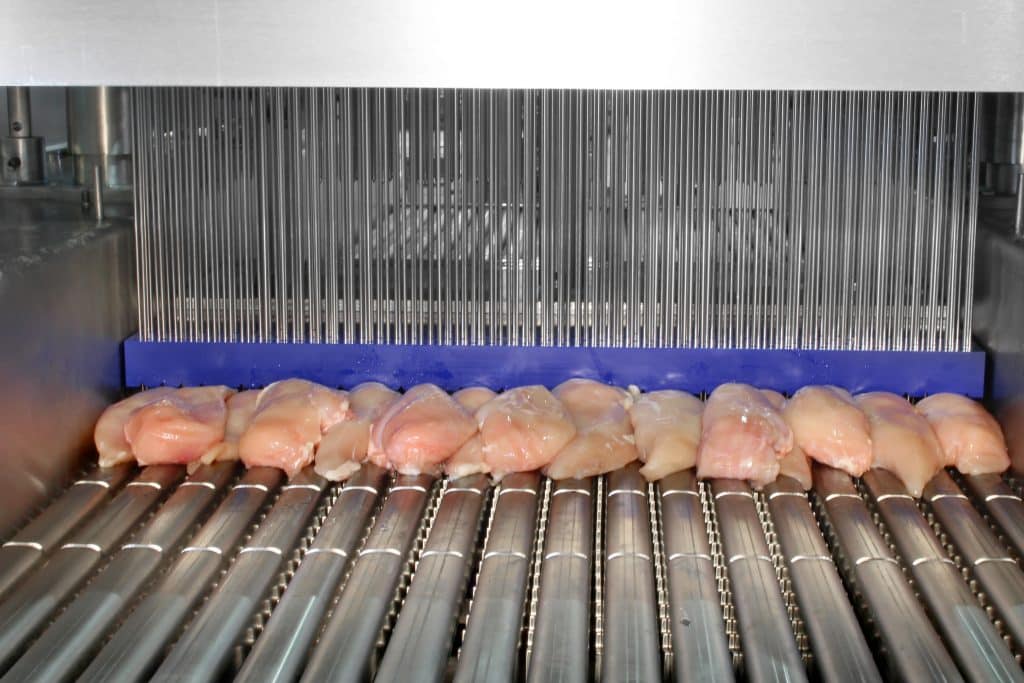

The HPI 450 S, 650 S and 1000 S are the servo-controlled injectors with transport belts from the HPI series. They are produced in order to inject small poultry parts or fish exactly and in order to realize an easy connection to IQF lines. In addition, with the HPI S, a special process for the production of vegan meat substitutes was successfully established on the market.

pneumatic springed needles

The pressure of the single pneumatic springed needles can be adjusted steplessly. All needles are easily removable without any tools for easy cleaning. We offer different types of needles in 4, 3, 2,5 or 1,9 mm in order to meet the requirements of the different products.

<< Injector Type HPI 650 S

with double pipe heat exchanger, cooling, transport belt, antisedimentation unit, fill level sensor and many more.

PRECISION AND STABILITY

The injector control is characterized by user friendliness. Stroke speed and beam walk speed are coupled mechanically through the robust drive with frequency converter and are absolute synchronous.

The pressure of the injector is steplessly adjustable by frequency converter driven centrifugal pump and can be read off the display or manometer.

The product move has been deviced for homogen stitch arrangement. This ensures a constant product quality.

Injector Data

| HPI 300 | HPI 350 | HPI 450 | HPI 650 | HPI 450 S | HPI 650 S | HPI 1000 S | |

|---|---|---|---|---|---|---|---|

| working width in mm | 300 | 350 | 450 | 650 | 450 | 650 | 1.000 |

| advance in mm/stroke | 15/30 | 30/60 | 41/82 | 41/82 | 115/230 | 115/230 | 115/230 |

| quantity of needles injector with single head | 24 | 50 or 102 | 108 or 167 | 160 or 243 | 435 | 630 | 968 |

| quantity of needles injector with double head | — | — | 216 or 334 | 320 or 486 | 260 | 384 | 594/890 |

| transport system | transport belt | transport belt | transport belt | ||||

| stroke height in mm | 200 | 200 | 200 | 200 | 40 – 230 | 40 – 230 | 40 – 230 |

| brine pressure in bar | 0,5 – 4 | 0,5 – 4 | 0,5 – 4 | 0,5 – 4 | 0,5 – 4 | 0,5 – 4 | 0,5 – 4 |

| stroke speed | 50 | 15 – 55 | 15 – 55 | 15 – 55 | 15 – 55 | 15 – 55 | 15 – 90 |

| connection power in kW | 2 | 8 | 11 | 18 | 30 | 35 | 35 |

| length in mm | 1.510 | 1.920 | 2.090 | 2.570 | 3.200 | 3.200 | 3.200 |

| width in mm | 700 | 1.140 | 1.400 | 1.670 | 1.550 | 1.750 | 1.530 |

| height in mm | 1.930 | 2.050 / 2.370 | 2.200 | 2.200 | 2.250 | 2.250 | 2.250 |

| weight in kg | 380 | 460 | 1.400 | 1.600 | 1.700 | 1.900 | 2.240 |

Changes reserved.